Inventory management has become one of the most crucial factors of every business model, especially for eCommerce retailers. In such a competitive market, any possible problems occurring within the inventory process can properly hurt the entire operation. That’s why many modern entrepreneurs have poured a huge amount of time and effort into optimizing the process. Meanwhile, others still do not clearly understand how important it is to track inventory on a regular basis.

What is inventory management?

Inventory management is a part of the supply chain that systematically involves sourcing, storing, and selling inventory (including both raw materials and finished products). The inventory process differs between businesses depending on the types of products and channels to distribute them. In particular, big operations, with complicated supply chains and inventory processes, often face the huge problem of balancing between excess inventory and shortage of product supply.

Why do retailers need inventory management?

Save cost and time

Traditionally, small to medium-sized businesses monitor their inventory database by using manual tools such as Excel or Google Sheets. This method not only costs them loads of time but also money to deal with human mistakes. On the contrary, an effective and modern inventory management system allows businesses to automate many tasks such as counting or updating stock levels and also enhancing the accuracy of the process.

Moreover, retailers can also reduce time maintaining stock as well as guarantee a streamlined sales and inventory process. For example, they can ensure that their certain products do not stay on shelves for long while there are shortages of others. As a result, retailers can significantly raise their profits.

Forecast and report demand

Some inventory management software can generate insightful reports based on data in hand and identify consuming trends in the changing market. Retailers can come up with reliable demand forecasting and data-driven plans from these reports. Also, by well planning and forecasting, they are able to reduce the risk of revenue loss due to excess or obsolete stock and free up their cash flows.

Better customer service

A streamlined inventory management system enables retailers to fulfill instantly every customer orders thanks to their appropriate stock level in hand. In particular, during the high peak season, the number of orders may significantly rise during a limited time period. It is necessary that retail businesses have enough products available to serve their customers. Inventory management is also beneficial in terms of product returns. With a powerful system, retailers can ensure these requests are fulfilled in a timely manner without posing any further problems to the whole process.

Support shipping service

Late delivery is a common problem that stems from stockouts, which produces negative impacts on the sales process as well as brand reputation. Inventory management helps retailers to monitor when and where products are delivered to customers, which makes great contributions to manage customer expectations.

Types of inventory management

As mentioned above, depending on characteristics and requirements of each business, inventory management systems are different. In general, there are three types of inventory management that are commonly used nowadays.

Perpetual inventory

Perpetual inventory or also known as continuous inventory is the method that uses point of sale systems to constantly update inventory quantities and availability in real-time. This type of inventory management records and showcases every detailed change in the amount of inventory in stock as well as the stock level during the operating process. Thanks to these immediate reports, retailers are timely informed of possible problems such as overstock or understock and come up with important decisions.

Just-in-time (JIT) inventory

Another type of inventory management is Just-in-time (JIT) inventory, which shortens the amount of time storing raw materials for manufacturing and distributing. In other words, when adopting this system, businesses minimize their inventory in hand and only reorder materials when their previous batch of finished products are ready to be sold.

The JIT inventory system supports retailers to reduce inventory expenses on storage costs and lean their manufacturing process while still increasing efficiency. However, when opting for this method, businesses are required to closely follow market trends and accurately forecast product demand in the future.

Additionally, retailers may also encounter unexpected issues such as delayed shipment during Covid 19 pandemics. According to Statista, in 2020, about 20% of supply chains worldwide were interrupted by Covid 90 pandemics. Notably, the interruption in supply chains has broken many retail processes and caused a serious loss of profit.

ABC inventory

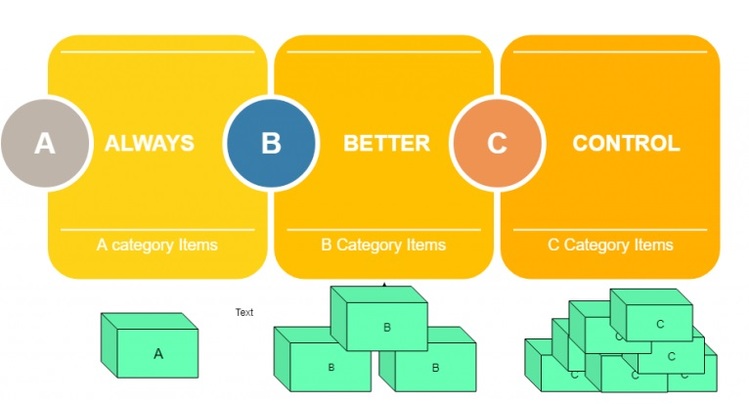

The third method mentioned in this article is called the ABC technique in inventory management. The ABC inventory monitors inventory items based on their importance. Commonly, stores will rank their inventory in order of demand, cost, and risk data.

To illustrate, items in Class A are the most important due to their high sales volume. Items in Class B are the next important. The Class C items are less important than the two formers. In fact, retail companies usually have more than three classes of items to manage their inventory effectively.

By classifying inventory items, businesses are able to gain an in-depth understanding of which products or services are most valuable and allocate a proper time and money budget for them.

Tips to better manage your inventory

Integrate technology

The development of technology has significantly changed almost every aspect of modern business. In the same way, using technology is considered the best way to stay on top of the industry. Retailers can opt for helpful technological solutions to keep track of every item moving in and out of their inventory, transfer items to the right locations at the right time, and also timely identify problems with their stock. In fact, approximately 66% of modern retail owners have planned to automate their processes with new technology solutions.

There are lots of software existing that can greatly support modern retailers. Taking the POS system as an example. This system can not only optimize the sales process in stores but also efficiently deal with inventory problems. A feature-rich POS system like ConnectPOS can even automatically produce insightful reports on store performance and be customized to best fit in with the business.

Follow demand trend

The retail industry, as well as customer behavior, are changing constantly over time. And retailers are required to adapt well to these changes in order to survive and thrive in the market. In fact, demand trends can tell brands loads of valuable information. By analyzing existing data, retailers can predict the future and know what they should do next and how. Timely catching up with emerging trends can help retailers become the leader in their market and step ahead of other competitors.

Choose reliable suppliers

When it comes to a great supplier, it is not only about providing high-quality materials but also delivering them on time. Both of these two factors play a crucial role in streamlining the retail process and offering better customer services. If suppliers fail to guarantee their product quality and delivery time, retail stores may struggle with maintaining an appropriate stock level and provide well-priced products to satisfy their customers.

Track sales

It is important to bear in mind that tracking sales is an important task. At the end of the day, retailers must update the number of items that they have sold, what types of items are fast-moving or slow-moving, and also the total quantity of current inventory. Based on this information, retailers will have an overall picture of their business system and make better decisions to handle possible inventory problems.

Set reorder time

Low-level stock may cause manufacturers difficulties to produce the required amount of products and loss of profit. Also, retail businesses should not maintain more inventory than what can be sold, which may reduce process flexibility. By setting accurate reorder time, retailers can avoid out-of-stock items, especially during high peak seasons, and continuously manufacture products to fulfill the market demand.

Have policies on what to do with deadstock

Deadstock refers to items that can not be sold and also do not appear to be sold in the future. These items cause a profit loss and also take space for other products. This is a common problem with inventory management that the majority of retailers have encountered, especially with seasonal items. These items should be soon released in order to make room for new inventory. To deal with this problem, stores can consider creating special programs such as offering discounts or selling them in bundles.

Optimize FIFO

First In, First Out (FIFO) is an inventory method that follows the natural flow of inventory which releases the oldest product in the inventory first. FIFO optimization is about streamlining this process in order to minimize the risk of deadstock and save space from unsalable items. Also, with this method, retailers can ensure that their products have a long life span when being sold to customers.

Conclusion

As you can see, inventory management produces profound impacts on every retail business. It is undeniable that this major determinant can make or break a retailer. However, due to many factors that need taking into consideration, perfecting an inventory system is never an easy task. Fortunately, in the new era of technology, many inventory management solutions like POS or ERP systems have been developed and used worldwide. It is noted that each software will provide particular features to handle different problems. Hence, make sure that you will carefully analyze and choose the best solutions for your business.